SMT reflow oveninkqubo imfuneko zombini ekupheleni Chip amacandelo solder ipleyiti welding kufuneka izimele.Xa i-pad idibaniswe nocingo oluphantsi kwendawo enkulu, indlela yokuwela umnqamlezo kunye ne-45 ° indlela yokukhwela kufuneka ikhethwe.Intambo ekhokelayo ukusuka kwindawo enkulu yocingo lomhlaba okanye umgca wamandla mkhulu kune-0.5mm, kwaye ububanzi bungaphantsi kwe-0.4mm;Intambo exhunywe kwi-pad ye-rectangular kufuneka itsalwe ukusuka kumbindi wecala elide le-pad ukuphepha i-Angle.

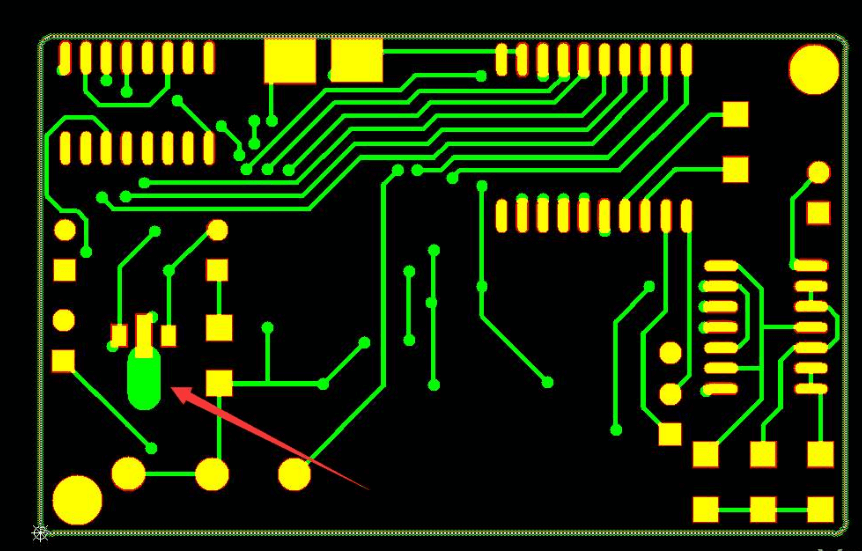

Jonga umfanekiso (a) ngeenkcukacha.

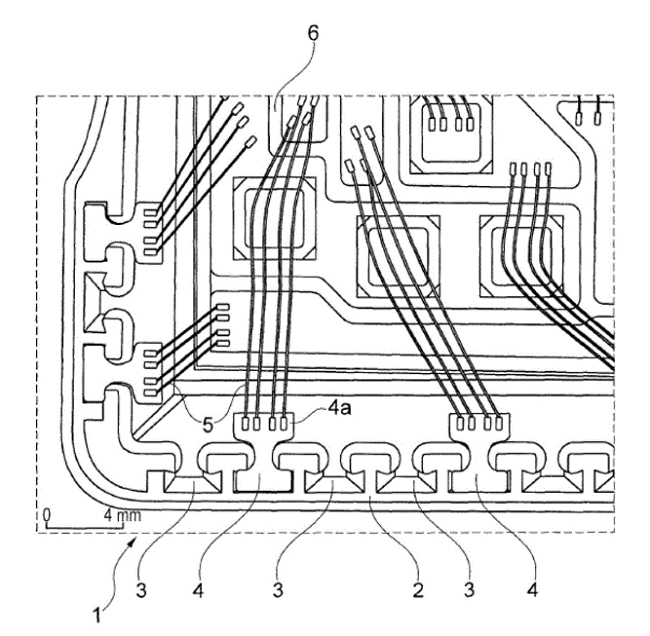

Iingcingo phakathi kweepads ze-SMD kunye neengcingo ezikhokelayo zeepads ziboniswa kumfanekiso (b).Umfanekiso ngumzobo wokudibanisa wephedi kunye nocingo oluprintiweyo

Umkhomba-ndlela kunye nokumila kocingo oluprintiweyo:

(1) Intambo eprintiweyo yebhodi yesekethe kufuneka ibe mfutshane kakhulu, ngoko ke, ukuba unokuthatha eyona imfutshane, ungahambi entsonkothileyo, landela inokulula ingabi ninzi, imfutshane hayi ixesha elide.Iluncedo olukhulu kulawulo lomgangatho webhodi yesekethe yePCB kwinqanaba lamva.

(2) Isalathiso socingo olushicilelweyo aluyi kuba nokugoba okubukhali kunye ne-Angle ebukhali, kunye ne-Angle yocingo oluprintiweyo aluyi kuba ngaphantsi kwe-90 °.Oku kungenxa yokuba kunzima ukugrumba ii-engile ezincinci zangaphakathi xa usenza iipleyiti.Kwiikona ezibukhali zangaphandle, i-foil iyakwazi ukukhupha okanye i-warp.Eyona ndlela yokuguqula inguqu ethambileyo, oko kukuthi, ii-angles zangaphakathi nangaphandle zekona ziyi-radians best.

(3) Xa ucingo ludlula phakathi kwee-gaskets ezimbini kwaye aluxhunywanga nabo, kufuneka lugcine umgama ophezulu kunye nolinganayo kubo;Ngokufanayo, imigama phakathi kweengcingo kufuneka ifane kwaye ilingane kwaye igcinwe ukuya phezulu.

Xa ukudibanisa iingcingo phakathi kwe-PCB pads, ububanzi beentambo bunokuba bufana nobubanzi beepads xa umgama phakathi kombindi weepads ungaphantsi kobubanzi obungaphandle beepads D;Xa umgama ophakathi phakathi kweepads mkhulu kune-D, ububanzi bocingo kufuneka buncitshiswe.Xa kukho iipads ezingaphezu kwe-3 kwiipads, umgama phakathi kwabaqhubi kufuneka ube mkhulu kune-2D.

(4) Xa udibanisa abaqhubi phakathi kwe-PCB pads, ububanzi bee-conductors bunokuba bufana nobubanzi beepads xa umgama phakathi kombindi we-pads ungaphantsi kwe-diameter yangaphandle ye-D yeepads;Xa umgama ophakathi phakathi kweepads mkhulu kune-D, ububanzi bocingo kufuneka buncitshiswe.Xa kukho iipads ezingaphezu kwe-3 kwiipads, umgama phakathi kwabaqhubi kufuneka ube mkhulu kune-2D.

(5) Ifoyile yobhedu kufuneka igcinelwe ucingo oluqhelekileyo lokumisa kangangoko kunokwenzeka.

Ukuze ukwandise amandla e-peel we-liner, umgca wokuvelisa ongeyena-conductive unokubonelelwa.

Ixesha lokuposa: Jun-30-2021