Okwangoku, abaninzi abavelisi bemveliso ye-elektroniki abaphambili ekhaya nakwamanye amazwe bacebise ingcamango entsha yokugcinwa kwezixhobo "ukugcinwa okuhambelanayo" ukuze kuncitshiswe ngakumbi impembelelo yogcino ekusebenzeni kakuhle kwemveliso.Oko kukuthi, xa i-oven yokubuyisela isebenza ngokuzeleyo, inkqubo yokutshintsha ukugcinwa ngokuzenzekelayo kwesixhobo isetyenziselwa ukugcinwa kunye nokugcinwa kwe-oven yokubuyisela ihambelana ngokupheleleyo nemveliso.Olu yilo luyishiya ngokupheleleyo ingcamango yokuqala "yokugcinwa kokuvala", kwaye iphucula ngakumbi ukusebenza kakuhle kwemveliso yomgca we-SMT wonke.

Iimfuno zokuphunyezwa kwenkqubo:

Izixhobo ezikumgangatho ophezulu zinokuvelisa izibonelelo kuphela ngokusetyenziswa kobungcali.Okwangoku, iingxaki ezininzi ezijongene noninzi lwabavelisi kwinkqubo yokuvelisa i-lead-free soldering ayiveli kuphela kwisixhobo ngokwayo, kodwa kufuneka isonjululwe ngohlengahlengiso kwinkqubo.

l Ukusekwa kwegophe lesithando somlilo

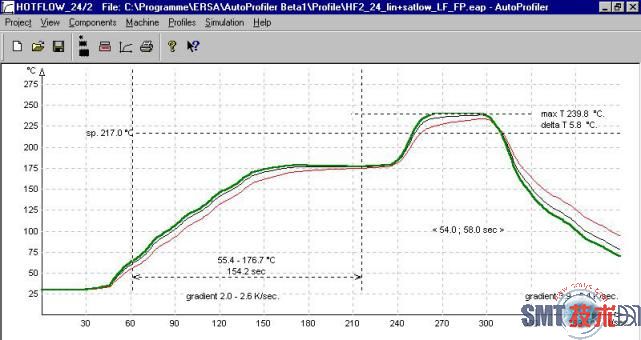

Ngenxa yokuba i-lead-free soldering window incinci kakhulu, kwaye kufuneka siqinisekise ukuba zonke ii-solder joints zingaphakathi kwefestile yenkqubo ngexesha elifanayo kwindawo yokuphinda ibuyele, ngoko ke, i-lead-free reflow curve ihlala ibeka "i-flat top" (i-flat top) ( jonga uMzobo 9).

Umzobo we-9 "I-Flat top" kwisimo se-curve yesithando somlilo

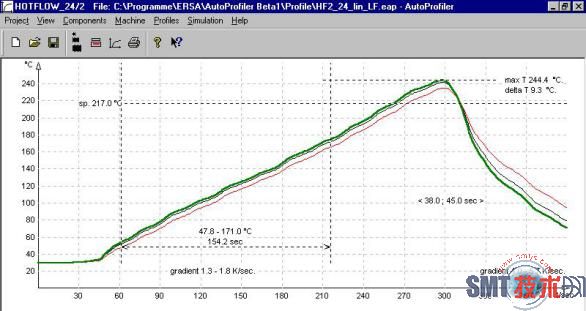

Ukuba amacandelo asekuqaleni kwibhodi yesiphaluka anomahluko omncinci kumthamo we-thermal kodwa avakalelwa ngakumbi kwi-thermal shock, kulungeleka ngakumbi ukusebenzisa i-curve "linear" yesithando somlilo.(Jonga umfanekiso 10)

Umzobo we-10 "Linear" ijika lobushushu besithando somlilo

Ukumiselwa kunye nokulungiswa kwegophe lobushushu bomlilo kuxhomekeke kwizinto ezininzi ezifana nezixhobo, amacandelo okuqala, i-solder paste, njl. Indlela yokumisela ayifani, kwaye amava kufuneka aqokelelwe ngokusebenzisa imifuniselo.

l Isoftware yokulinganisa igophe lobushushu besithando somlilo

Ngoko ngaba kukho ezinye iindlela ezinokusinceda ngokukhawuleza nangokuchanekileyo ukuseta ijika lobushushu besithando somlilo?Sinokuqwalasela ukuvelisa isoftware ngoncedo lwe-furnace curve simulation.

Phantsi kweemeko eziqhelekileyo, okoko sixelele isoftware imeko yebhodi yesekethe, imeko yesixhobo sokuqala, isithuba sebhodi, isantya setsheyini, iqondo lobushushu kunye nokukhethwa kwezixhobo, isoftware iyakulinganisa ijika lobushushu eliveliswe phantsi kweemeko ezinjalo.Oku kuya kulungelelaniswa ngaphandle kweintanethi de kufumaneke ijiko elanelisayo lobushushu beziko.Oku kunokonga kakhulu ixesha lokuba iinjineli zenkqubo zihlengahlengise ngokuphindaphindiweyo ijika, elibaluleke kakhulu kubavelisi abaneentlobo ezininzi kunye neebhetshi ezincinci.

Ikamva letekhnoloji ye-reflow soldering

Iimveliso zefowuni eziphathwayo kunye neemveliso zomkhosi zineemfuno ezahlukeneyo zokuphinda zifakwe kwi-solder, kunye nokuveliswa kwebhodi yesekethe kunye nemveliso ye-semiconductor ineemfuno ezahlukeneyo zokuphinda zifakwe kwi-solder.Imveliso encinci kunye neyomthamo omkhulu yaqala ukuhla kancinci, kwaye umahluko kwiimfuno zezixhobo zeemveliso ezahlukeneyo zaqala ukubonakala imihla ngemihla.Umahluko phakathi kwe-reflow soldering kwixesha elizayo awuyi kubonakaliswa kuphela kwinani leendawo zokushisa kunye nokukhethwa kwe-nitrogen, i-reflow soldering market iya kuqhubeka ihlulwe, nto leyo isalathiso sophuhliso olubonakalayo lwe-teknoloji ye-reflow soldering kwixesha elizayo.

Ixesha lokuposa: Aug-14-2020