Ukusetyenzwa kwetshiphu ye-SMT ngokuthe ngcembe ukuya kuxinaniso oluphezulu, uphuhliso loyilo lwepitch entle, ubuncinci bezithuba zoyilo lwamalungu, kufuneka kuthathelwe ingqalelo amava omenzi we-SMT kunye nokugqibelela kwenkqubo.Uyilo lwesithuba esincinci samacandelo, ukongeza ekuqinisekiseni umgama wokhuseleko phakathi kwee-SMT pads, kufuneka kwakhona kuthathelwe ingqalelo ukugcinwa kwamacandelo.

Qinisekisa isithuba esikhuselekileyo xa ubeka amacandelo

1. Umgama wokhuseleko unxulumene ne-stencil flare, ukuvulwa kwe-stencil kukhulu kakhulu, ubukhulu be-stencil bukhulu kakhulu, ukunyanzeliswa kwe-stencil akwanelanga i-deformation ye-stencil, kuya kubakho i-welding bias, ekhokelela kumacandelo nakwisekethe emfutshane ye-tin.

2. Emsebenzini onjenge-soldering yezandla, i-solder ekhethiweyo, i-tooling, i-rework, ukuhlolwa, ukuvavanya, ukudibanisa kunye nezinye iindawo zokusebenza, umgama uyafuneka.

3. Ubungakanani besithuba phakathi kwezixhobo zetshiphu bunxulumene noyilo lwephedi, ukuba iphedi ayinwenwanga ngaphandle kwepakethe yecandelo, intlama ye-solder iya kunyonyobeleka ecaleni kwecala lecandelo le-solder, icandelo elibhityileyo kuba lula. kukubhulorho nkqu isekethe emfutshane.

4. Ixabiso lokhuseleko lwesithuba phakathi kwamacandelo alikho ixabiso elipheleleyo, njengoko izixhobo zokuvelisa azifani, kukho ukungafani kwamandla okwenza indibano, ixabiso lokhuseleko linokuchazwa njengobunzima, kunokwenzeka, ukhuseleko.

Iziphene kuyilo lwecandelo elingafanelekanga

Amacandelo kwi-PCB kwi-beko lofakelo oluchanekileyo, luyinxalenye ebaluleke kakhulu yokunciphisa iziphene ze-welding, i-party layout, kufuneka ibe kude kangangoko kunokwenzeka ukusuka ekuphambukeni kwendawo enkulu kunye neendawo zoxinzelelo oluphezulu, ukuhanjiswa kufuneka kube ngokufanayo njengoko kunokwenzeka, ingakumbi amacandelo kunye umthamo thermal enkulu, kufuneka uzame ukuphepha ukusetyenziswa PCB oversized ukuthintela warping, uyilo uyilo olulambathayo kuya kuchaphazela ngqo PCBA ukuhlangana kunye nokuthembeka.

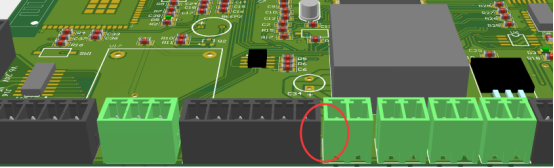

1. Umgama wesiqhagamshelo ukufutshane kakhulu

Izihlanganisi ngokuqhelekileyo zizinto eziphezulu, kwi-layout yomgama wexesha elisondele kakhulu, elihlanganiswe ecaleni komnye emva kokuba isithuba sincinci kakhulu, asinakho ukuphinda sisebenze.

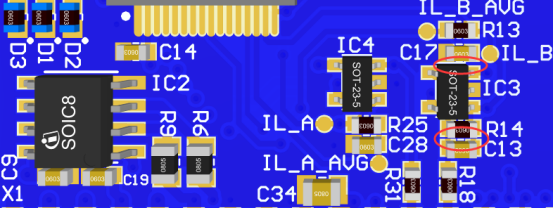

2. Umgama wezixhobo ezahlukeneyo

Kwi-SMT, ngenxa yesithuba esincinci sezixhobo ezithanda ukuvala ibhulorho, izixhobo ezahlukeneyo zibhulabhula ngaphezulu kune-0.5mm nangaphantsi kwesithuba, ngenxa yesithuba esincinci, ngoko uyilo lwetemplate yestencil okanye ukushicilela okushiyiweyo kulula kakhulu ukuvelisa. ibhuloho, kwaye isithuba samacandelo sincinci kakhulu, kukho umngcipheko wesekethe emfutshane.

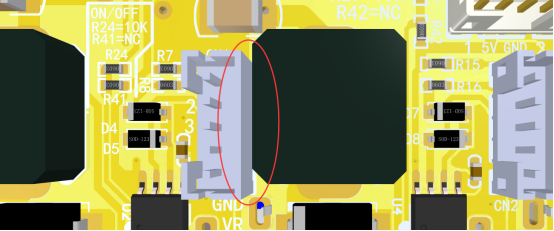

3. INdibano yamacandelo amabini amakhulu

Ubukhulu bamacandelo amabini ahlanganiswe ngokusondeleyo, kuya kubangela ukuba umatshini wokubeka kwindawo yokubekwa kwecandelo lesibini, uthinte umphambili uthunyelwe amacandelo, ukufumanisa ingozi ebangelwa ngumatshini ngokuzenzekelayo ukucima.

4. Amacandelo amancinci phantsi kwamacandelo amakhulu

Amacandelo amakhulu angaphantsi kokubekwa kwamacandelo amancinci, aya kubangela imiphumo yokungakwazi ukulungisa, umzekelo, ityhubhu yedijithali phantsi kwe-resistor, iya kubangela ubunzima bokulungisa, ukulungiswa kufuneka kuqala kususe ityhubhu yedijithali ukulungisa, kwaye kunokubangela umonakalo wetyhubhu yedijithali. .

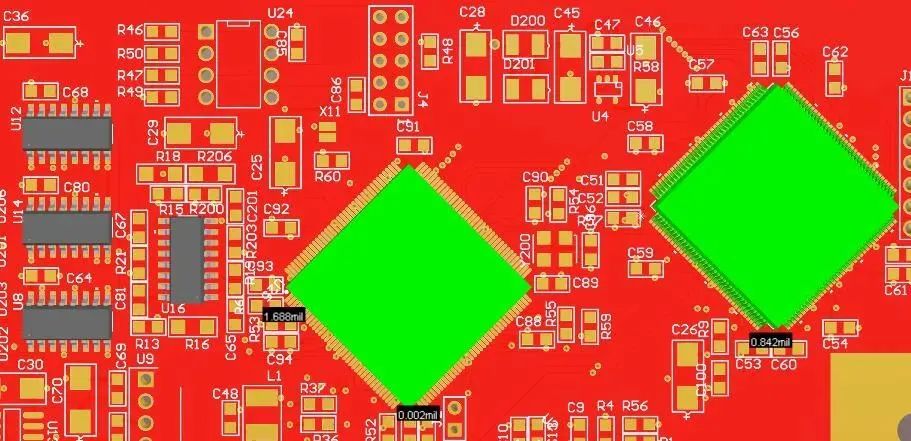

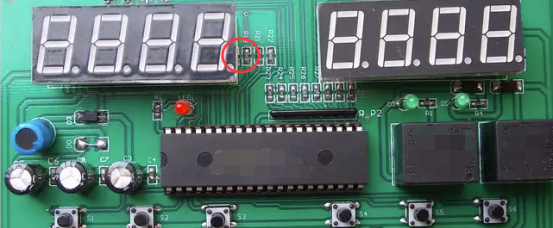

Imeko yesekethe emfutshane ebangelwa ngumgama osondele kakhulu phakathi kwamacandelo

>> Inkcazo yengxaki

Imveliso kwimveliso yetshiphu ye-SMT, yafumanisa ukuba umgama we-capacitor C117 kunye ne-C118 ungaphantsi kwe-0.25mm, imveliso ye-chip ye-SMT inomda we-tin omfutshane wesekethe.

>> Impembelelo yengxaki

Ibangele isiphaluka esifutshane kwimveliso kwaye yachaphazela umsebenzi wemveliso;ukuyiphucula, kufuneka sitshintshe ibhodi kwaye sandise umgama we-capacitor, echaphazela nomjikelezo wophuhliso lwemveliso.

>> Ukwandiswa kwengxaki

Ukuba isithuba asivalwanga ngokukodwa, kwaye isiphaluka esifutshane singabonakali, kuya kubakho ingozi yokhuseleko, kwaye imveliso iya kusetyenziswa ngumsebenzisi ngeengxaki zesiphaluka ezimfutshane, ezibangela ilahleko engenakucingelwa.

Ixesha lokuposa: Apr-18-2023