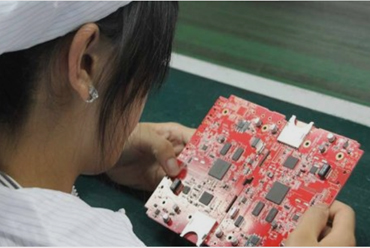

Indibano yePCB iDibaniso yesiphene isebenzisa uHlolo oluSebenzayo oluSebenzayo (AOI)

Indibano yePCB iDibaniso yesiphene isebenzisa uHlolo oluSebenzayo oluSebenzayo (AOI)

Ukuhlola okuSebenzayo okuSebenzayo (i-AOI), oluyi-automated visual inspection of the Printed Circuit Board (PCB), ibonelela nge-100% icandelo elibonakalayo kunye nokuhlolwa kwe-solder-joint.Le ndlela yokuvavanya ibisetyenziswa kwimveliso yePCB phantse amashumi amabini eminyaka.Idlala indima ebalulekileyo ekuqinisekiseni ukuba akukho ziphoso ezizenzekelayo kwindibano.Ubuchwephesha, obusebenzisa izibane, iikhamera, kunye neekhompyuter zembono, zibandakanyiwe kwinkqubo yokudityaniswa ukuqinisekisa olona mgangatho uphezulu unokwenzeka kwisigaba ngasinye somjikelo wobomi bemveliso.Indlela yenza ukuba kuhlolwe ngokukhawuleza nangokuchanekileyo kwaye kunokusetyenziswa kwizigaba ezahlukeneyo zenkqubo yokuvelisa.Ke, zeziphi zonke izinto ezinokujongwa kwisixhobo sokuHlola okuSebenzayo (AOI) kwiIndibano yePCB?

Ukufunyanwa Kweziphene Ngokusebenzisa i-AOI

Ngokukhawuleza ukuba iimpazamo zibonwa, kuya kuba lula ukwenza imveliso yokugqibela ihambelane neemfuno zoyilo ngaphandle kweziphene.Le teknoloji eyaziwayo, eyamkelekileyo inokusetyenziselwa ukujonga oku kulandelayo kwindibano yePCB:

- Amaqhuqhuva, imikrwelo namabala

- Iisekethe ezivulekileyo, iifutshane kunye nokunciphisa i-solder

- Amalungu angachanekanga, angekhoyo kwaye agqwethiweyo

- Indawo yokuncamathelisa engonelanga, ukuthanjiswa, kunye nebhuloho

- Iitshiphusi ezilahlekileyo okanye ezilungelelanisiweyo, iitshiphusi ezigoso kunye neziphene zokuqhelaniswa netshiphu

- Iibhulorho ze-Solder, kunye neentambo eziphakanyisiweyo

- Ukwaphulwa kobubanzi bomgca

- Ukwaphulwa kwezithuba

- Ubhedu olugqithisileyo, kunye nephedi engekhoyo

- Landela iifutshane, amafutshane, ukutsiba

- Iziphene zendawo

- Izahlulo zamacandelo, ipolarity yecandelo,

- Ubukho becandelo okanye ukungabikho, ikhomponenti i-skew ukusuka kwiipads zokunyuka komphezulu

- Amalungu e-solder ngokugqithiseleyo kunye neengxube ze-solder ezingonelanga

- Amalungu ajingiwe

- Ncamathelisa ujikeleze umkhondo, iibhulorho ze-solder, kunye nokubhaliswa kwe-solder paste

Ngezi mpazamo zifunyenwe kwinqanaba lokuqala, abavelisi banokuvelisa ibhodi kwimigangatho efunekayo.Ukwenza igalelo kwiinkqubo zovavanyo, kukho izixhobo ezininzi ezifumanekayo ezinokukhanya okuphezulu, i-optics, kunye nesakhono sokuseta umfanekiso wokhuselo olukhethekileyo.Aba matshini banikezela ngokusebenza okulula, okukrelekrele kunye namandla, okukhokelela ekunciphiseni iindleko zakho zokuphinda usebenze kunye nokuphucula inkqubo yokuvavanya.I-AOI yindlela yokuvavanya ebalulekileyo emisela umgangatho uwonke webhodi, kubalulekile ukufumana inkonzo kwiinkampani eziphambili.Kuhlala kulukhetho olufanelekileyo ukunxulumana nabavelisi be-PCB ababonelela ngovavanyo lwe-AOI ngesandla ngesandla.Oku kunceda umenzi ukuba avavanye ibhodi kuwo onke amanqanaba endibano ngaphandle kokulibazisa.

Ixesha lokuposa: Jun-15-2020