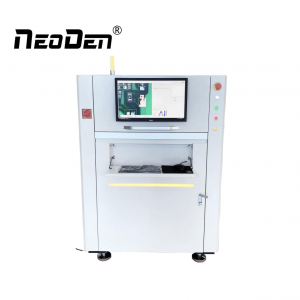

NgelixaUmatshini we-SMT AOIingasetyenziselwa kwiindawo ezininzi kumgca wemveliso ye-SMT ukufumanisa iziphene ezithile, izixhobo zokuhlola i-AOI kufuneka zibekwe kwindawo apho ezona ziphene zininzi zinokuchongwa kwaye zilungiswe kwangethuba.Kukho iindawo ezintathu eziphambili zokujonga:

NgelixaUmatshini we-SMT AOIingasetyenziselwa kwiindawo ezininzi kumgca wemveliso ye-SMT ukufumanisa iziphene ezithile, izixhobo zokuhlola i-AOI kufuneka zibekwe kwindawo apho ezona ziphene zininzi zinokuchongwa kwaye zilungiswe kwangethuba.Kukho iindawo ezintathu eziphambili zokujonga:

Emva kokuba i-solder paste ishicilelwe

Ukuba inkqubo yokushicilela i-solder paste ihlangabezana neemfuno, inani le-ICT defects lingancitshiswa kakhulu.Iziphene zoshicilelo eziqhelekileyo ziquka oku kulandelayo:

A.Itoti yokuthambisa enganelanga kwiumshicileli westencil.

B. I-solder eninzi kakhulu kwi-solder pad.

C. Ukungahambi kakuhle kwe-solder kwi-solder pad.

D. Solder ibhulorho phakathi pads.

Kwi-ICT, ukuba nokwenzeka kweziphene ngokubhekiselele kwezi meko kuhambelana ngokuthe ngqo nobunzima bemeko.Itoti encinci ayifane ikhokelele kwiziphene, ngelixa iimeko ezinzima, njengetoti esisiseko, phantse zisoloko zikhokelela kwiziphene kwi-ICT.I-solder engafanelekanga ingaba yimbangela yokulahlekelwa kwecandelo okanye i-solder evulekileyo.Nangona kunjalo, ukwenza isigqibo sokuba ibekwe phi i-AOI kufuna ukuqaphela ukuba inxalenye yelahleko inokwenzeka ngenxa yezinye izizathu ekufuneka zibandakanywe kwisicwangciso sohlolo.Olu hlolo lwendawo luxhasa ngokuthe ngqo ukulandelwa kwenkqubo kunye nophawu.Idatha yolawulo lwenkqubo yobungakanani kweli nqanaba ibandakanya ukuprintwa kwe-offset kunye nolwazi lwevolumu ye-solder, ngelixa ulwazi olusemgangathweni malunga ne-solder eprintiweyo nayo iveliswa.

Ngenxa yereflow oven

Ukuhlolwa kwenziwa emva kokuba icandelo lifakwe kwi-solder paste ebhodini kwaye phambi kokuba i-PCB ifakwe kwi-reflow furnace.Le yindawo eqhelekileyo yokubeka umatshini wokuhlola, njengoko uninzi lweziphene ukusuka kushicilelo lwe-solder paste kunye nokubekwa koomatshini kunokufumaneka apha.Ulwazi lolawulo lwenkqubo yobungakanani oluveliswe kule ndawo lubonelela ngolwazi malunga nokulungelelaniswa koomatshini be-chip abanesantya esiphezulu kunye nezixhobo zokuxhoma zecandelo elivaliweyo.Olu lwazi lungasetyenziselwa ukuguqula ukubekwa kwecandelo okanye ukubonisa ukuba isixhomi sifuna ulungelelwaniso.Ukuhlolwa kwale ndawo kuhlangabezana nenjongo yokulandelwa kwenkqubo.

Emva kwe-reflow soldering

Khangela ekupheleni kwenkqubo ye-SMT, eyona ndlela idumileyo ye-AOI, kuba kulapho zonke iimpazamo zendibano zinokufunyanwa khona.Ukuhlolwa kwe-Post-reflow ibonelela ngenqanaba eliphezulu lokhuseleko ngenxa yokuba ichonga iimpazamo ezibangelwa ukuprintwa kwe-solder paste, ukunyuswa kwecandelo, kunye nenkqubo yokubuyisela kwakhona.

Ixesha lokuposa: Dec-11-2020