1) I-stencil ye-Electroforming

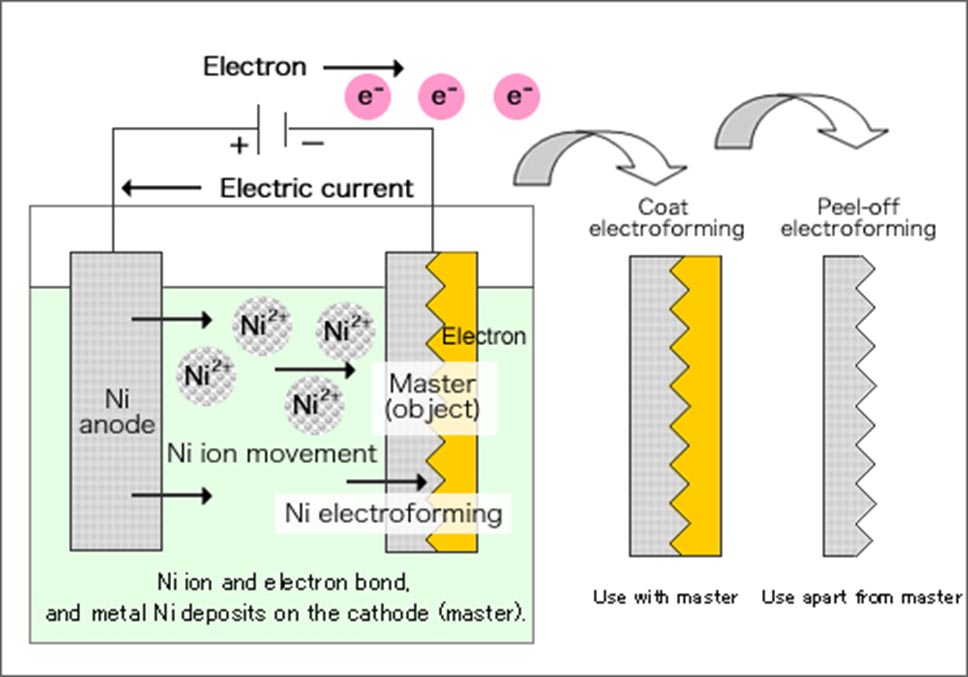

Umgaqo wokuvelisa i-electroformed stencil: itemplate ye-electroformed yenziwe ngokuprinta izinto ze-photoresist kwi-conductive metal base plate, kwaye emva koko nge-masking mold kunye nokuvezwa kwe-ultraviolet, kwaye ke itemplate ebhityileyo i-electroformed kulwelo lwe-electroforming.Enyanisweni, i-electroforming ifana ne-electroplating, ngaphandle kokuba i-nickel sheet emva kwe-electroforming inokuchithwa kwi-plate ephantsi ukuze yenze i-stencil.

I-stencil ye-Electroforming inezi mpawu zilandelayo: akukho xinzelelo ngaphakathi kwiphepha lensimbi, udonga lomngxuma lulula kakhulu, i-stencil ingaba nayiphi na ubukhulu (ngaphakathi kwe-0.2mm, ilawulwa yi-electroforming time), i-disadvantage kukuba iindleko ziphezulu.Lo mzobo ulandelayo luthelekiso lomnatha wensimbi ye-laser kunye nodonga lwentsimbi ye-electroformed.Udonga olugudileyo lomngxuma we-mesh yensimbi ye-electroformed inesiphumo esingcono sokudiliza emva kokushicilela, ukuze umlinganiselo wokuvula ube ngaphantsi kwe-0.5.

2) I-Ladder stencil

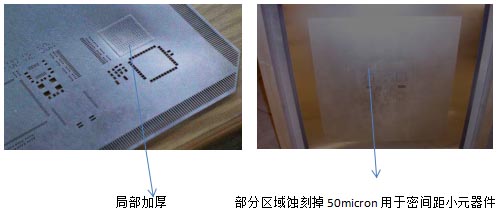

Umnatha wentsimbi onyathelweyo unokujiya okanye ucuthwe.Inxalenye ejiyileyo isetyenziselwa ukuprinta iipads ze-solder ezifuna isixa esikhulu se-solder paste, kunye nenxalenye ejiyileyo ibonwa nge-electroforming, kwaye ixabiso liphezulu.Ukunciphisa kuphunyezwa ngokukrolwa kweekhemikhali.Icandelo elincitshisiweyo lisetyenziselwa ukuprinta iipads zamacandelo amancinci, okwenza ukuba umphumo wokunciphisa ube ngcono.Abasebenzisi abajonga kakhulu iindleko bayacetyiswa ukuba basebenzise i-chemical etching, enexabiso eliphantsi.

3) I-Nano Ultra Coating

Ukugquma okanye ukubethelela umaleko we-nano-coating kumphezulu we-mesh yensimbi, i-nano-coating yenza udonga lomngxuma lugxothe i-solder paste, ngoko ke umphumo we-demolding ungcono, kwaye ukuzinza kwevolumu ye-solder paste yokushicilela kuhambelana ngakumbi.Ngale ndlela, umgangatho wokuprinta uqinisekisiwe ngakumbi, kwaye inani lokucoca kunye nokusula i-mesh yensimbi nalo lingancitshiswa.Okwangoku, uninzi lweenkqubo zasekhaya zisebenzisa kuphela umaleko we-nano-coating, kwaye umphumo uyancipha emva kwenani elithile lokushicilela.Kukho i-nano-coatings efakwe ngokuthe ngqo kwi-mesh yensimbi, enempembelelo engcono kunye nokuqina, kwaye ngokuqinisekileyo iindleko ziphezulu.

3. Inkqubo yokubumba i-solder kabini.

1) Ukuprinta / Ukuprinta

Oomatshini ababini bokushicilela basetyenziselwa ukuprinta kunye nokwenza i-solder paste.Eyokuqala isebenzisa i-stencil eqhelekileyo ukuprinta iipads zamacandelo amancinci ane-pitch enhle, kwaye eyesibini isebenzisa i-stencil ye-3D okanye i-stencil yesinyathelo ukuprinta iipads zamacandelo amakhulu.

Le ndlela ifuna oomatshini ababini bokushicilela, kwaye ixabiso lestencil nalo liphezulu.Ukuba i-stencil ye-3D isetyenzisiwe, i-comb scraper iyadingeka, eyandisa iindleko kunye nokusebenza kakuhle kwemveliso kuphantsi.

2) Ukuprinta / ukutshiza inkonkxa

Umshicileli wokuqala we-solder paste uprinta i-close-pitch pads encinci yecandelo, kwaye umshicileli we-inkjet wesibini uprinta iipadi zecandelo elikhulu.Ngale ndlela, isiphumo sokubumba i-solder silungile, kodwa ixabiso liphezulu kwaye ukusebenza kakuhle kuphantsi (kuxhomekeke kwinani leepads zecandelo elikhulu).

Abasebenzisi bangakhetha ukusebenzisa izisombululo ezininzi ezingentla ngokwemeko yabo.Ngokumalunga neendleko kunye nokusebenza kakuhle kwemveliso, ukunciphisa ubukhulu be-stencil, usebenzisa i-stencil ye-aperture ratio ye-low-required area, kunye ne-step stencils zikhetho ezifanelekileyo ngakumbi;abasebenzisi abanemveliso ephantsi, iimfuno ezikumgangatho ophezulu, kunye nabasebenzisi abangenaxabiso banokukhetha iNkqubo yoshicilelo yejethi.

Ixesha lokuposa: Aug-07-2020