Ukubekwa kunye nokubekwa kweincwadi yesandlasoldershicilelaer

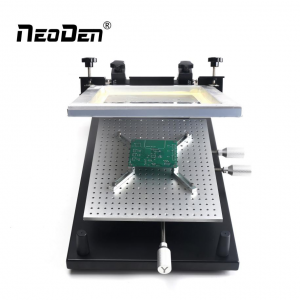

Kumgca wemveliso we-SMT, ushicilelo kukutyibilika uncamathiselo lwe-solder kwiipadi ezihambelanayo kwi-PCB ukulungiselela isiqwenga esilandelayo.Umshicileli we-solder owenziwe ngesandla ubhekisa kwinkqubo yoshicilelo lwesolder ngesandla usebenzisa umatshini wokushicilela.

Inkqubo yokusebenza komshicileli we-solder we-manual ibandakanya ukubeka ipleyiti, ukubeka, ukushicilela, ukuthatha ipleyiti kunyeukucoca umnatha wentsimbi.

- Umnatha wentsimbi esisigxina

Sebenzisa isixhobo sokulungisa ukulungisa i-mesh yensimbi kumatshini wokushicilela.Emva kokulungiswa, qinisekisa ukuba i-mesh yensimbi kunye ne-PCB idibene neflethi.Akukho qhagamshelwano olungalinganiyo okanye olunecala elinye olunokuthi lwenzeke, ngaphandle koko kulula ukubangela ukuwa kwendawo yokushicilela i-solder paste, echaphazela umgangatho wokushicilela kunye nobomi benkonzo ye-mesh yensimbi. - Indawo yePCB

Ushicilelo lweManuwali, iPCB ithatha indawo yokubekwa komphetho wepleyiti, oko kukuthi, ukubeka ngokwendawo yomngxuma wokumisa ebhodini.Emva kokumiswa, i-mesh ye-mesh yensimbi kufuneka ihambelane ngokuchanekileyo kunye neepads ezihambelanayo zePCB.Ukuze ube nenkangeleko edibeneyo ye-solder, ngokuqhelekileyo kufuneka ukuba i-solder paste kunye ne-solder pad dislocation degree ingaphantsi kwe-10%.

Iprintwe ngesandla amanyathelo ama-4

- Inkqubo yoshicilelo ikakhulu inala manyathelo mane alandelayo.

(1) iqondo lobushushu kunye nokuxuba intlama ye-solder elungileyo ephakanyiswe kwaye incamathele kumnatha wentsimbi, intlama ye-solder ayithathi kakhulu, kunye noshicilelo kunye nokudibanisa. - I-PCB eza kushicilelwa kufuneka ibekwe kwicala elichanekileyo kwitafile yoshicilelo, ubeke phantsi umnatha wentsimbi, kwaye ukhangele ukuba i-mesh ihambelana ngokuchanekileyo kunye ne-solder pad ye-PCB.

- Khupha i-solder paste nge-scraper ukwenza i-solder incamathelise kwi-steel net roll kwaye uprinte ukusuka phezulu ukuya ezantsi kwicala le-PCB.

- Susa iPCB eprintiweyo kwitafile yoshicilelo.Jonga ukuba kukho ukuvuza, itoti eninzi, inkonkxa encinci, kunye nesiganeko sokushicilela.Ukuba awufanelekanga, hlamba i-solder paste ngebhodi yokuhlamba kwaye uyiprinte kwakhona emva kokuba ibhodi yomile.

Sikwabonelelaumshicileli we-solder semi-automatic, ukuba ufuna, zive ukhululekile ukuqhagamshelana nathi.

Ixesha lokuposa: Jan-21-2021