Ngokutsho kwe-EU's RoHS Directive (i-Directive Act yePalamente yaseYurophu kunye neBhunga le-European Union malunga nokuthintelwa kokusetyenziswa kwezinto ezithile ezinobungozi kwizixhobo zombane kunye ne-elektroniki), Umyalelo ufuna ukuvinjelwa kwemarike ye-EU ukuthengisa i-elektroniki kunye nezixhobo zombane. izixhobo zombane ezinezinto ezintandathu ezinobungozi ezifana nelothe “njengemveliso eluhlaza” inkqubo engenalothe ethe yayindlela yophuhliso olungajikiyo ukusukela ngomhla woku-1 kuJulayi ka-2006.

Sele ingaphezulu kweminyaka emibini ukusukela oko inkqubo engakhokhelwanga iqalile ukusuka kwinqanaba lamalungiselelo.Uninzi lwabavelisi beemveliso ze-elektroniki e-China baqokelele amava amaninzi axabisekileyo kwinguqu esebenzayo ukusuka kwi-solder-free soldering ukuya kwi-solder-free soldering.Ngoku ukuba inkqubo yokukhokela esimahla iya ikhula ngakumbi nangakumbi, umsebenzi ekugxilwe kuwo uninzi lwabavelisi utshintshile ukusuka ekubeni ukwazi ukuphumeza imveliso engahlawulelwayo ukuya kwindlela yokuphucula ngokupheleleyo inqanaba le-solder engahlawulelwayo ukusuka kwimiba eyahlukeneyo efana nezixhobo. , izinto, umgangatho, inkqubo kunye nokusetyenziswa kwamandla..

Inkqubo yokuthengiswa kwe-lead-free reflow soldering yeyona nkqubo ibaluleke kakhulu kwi-teknoloji yangoku yokunyuka komhlaba.Isetyenziswe ngokubanzi kumashishini amaninzi aquka iiselfowuni, iikhompyutha, i-automotive electronics, iisekethe zolawulo kunye nonxibelelwano.Izixhobo zoqobo ze-elektroniki ziya kuguqulwa ukusuka kumngxunya ukuya kwindawo yokuxhoma ngaphezulu, kwaye ukuphinda kufakwe i-solder endaweni ye-solder ye-ave kuluhlu olubonakalayo yinto ecacileyo kushishino lokuthengisela.

Ke yeyiphi indima eza kudlala isixhobo sokuphinda siyidlale kwinkqubo ye-SMT ekhulayo engenalo lead?Makhe siyijonge ngokwembono yawo wonke umgca wokunyuka womphezulu we-SMT:

Wonke umgca wokunyuka womphezulu we-SMT uqulathe ngokubanzi iinxalenye ezintathu: umshicileli wesikrini, umatshini wokubeka kunye ne-oveni yokuqukuqela kwakhona.Koomatshini bokubeka, xa kuthelekiswa nabangenalothe, akukho mfuneko entsha yesixhobo ngokwaso;Kumatshini wokushicilela wesikrini, ngenxa yomahluko omncinci kwiipropati ezibonakalayo ze-lead-free kunye ne-lead solder paste, ezinye iimfuno zokuphucula zibekwe phambili kwisixhobo ngokwazo, kodwa akukho tshintsho lwekhwalithi;Umceli mngeni woxinzelelo olungenalo ilothe ngokuthe ngqo kwi-oven yokubuyisela kwakhona.

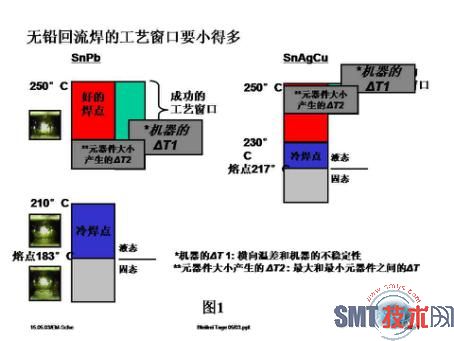

Njengoko nonke nisazi, indawo yokunyibilika ye-lead solder paste (Sn63Pb37) yi-183 degrees.Ukuba ufuna ukwenza i-solder edibeneyo, kufuneka ube ne-0.5-3.5um ubukhulu beekhompawundi ze-intermetallic ngexesha le-soldering.Iqondo lokushisa lokubunjwa kwe-intermetallic compounds liyi-10-15 degrees ngaphezu kwendawo yokunyibilika, eyi-195-200 ye-solder lead.isidanga.Ubushushu obuphezulu bezinto zokuqala ze-elektroniki kwibhodi yesekethe ngokuqhelekileyo ngama-240 degrees.Ngoko ke, kwi-lead soldering, i-window yenkqubo ye-solder efanelekileyo yi-195-240 degrees.

I-lead-free-soldering iye yazisa utshintsho olukhulu kwinkqubo ye-soldering kuba indawo yokunyibilika ye-lead-free solder paste itshintshile.I-lead-free solder paste esetyenziswa ngoku isetyenziswa ngoku i-Sn96Ag0.5Cu3.5 ene-melting point ye-217-221 degrees.I-soldering elungileyo engenalothe kufuneka kwakhona yenze imixube ye-intermetallic enobunzima obuyi-0.5-3.5um.Iqondo lokushisa lokubunjwa kwe-intermetallic compounds likwayi-10-15 degrees ngaphezu kwendawo yokunyibilika, eyi-230-235 degrees ye-solder-free soldering.Ekubeni ubushushu obuphezulu be-lead-free soldering ye-electronics original devices ayitshintshi, i-window ye-soldering yenkqubo efanelekileyo ye-lead-free soldering yi-230-240 degrees.

Ukuncitshiswa kakhulu kwenkqubo yefestile kuzise imingeni emikhulu yokuqinisekisa umgangatho we-welding, kwaye kuzise iimfuno eziphezulu zozinzo kunye nokuthembeka kwezixhobo zokuthengisela ezingenalo i-load.Ngenxa yomahluko weqondo lobushushu elisecaleni kwisixhobo ngokwaso, kunye nokwahluka kumthamo we-thermal wamacandelo okuqala e-elektroniki ngexesha lenkqubo yokufudumeza, i-soldering yenkqubo yobushushu befestile yoluhlu olunokulungiswa kulawulo lwenkqubo yokuthengisela i-lead-free reflow luba luncinci kakhulu. .Obu bubunzima bokwenyani bokuthengiswa kwe-lead-free reflow soldering.Ukuthelekisa okuthe ngqo kwefestile okukhokelayo kunye ne-lead-free-free reflow soldering process iboniswe kuMfanekiso 1.

Isishwankathelo, i-oven yokubuyisela idlala indima ebalulekileyo kumgangatho wokugqibela wemveliso ukusuka kumbono wenkqubo yonke yokukhokela.Nangona kunjalo, kwimbono yotyalo-mali kuwo wonke umgca wemveliso ye-SMT, utyalo-mali kwii-lead-free soldering furnaces kaninzi lubalela kuphela i-10-25% yotyalo-mali kuwo wonke umgca we-SMT.Kungenxa yoko le nto abaninzi abavelisi bezinto zombane batshintsha ngokukhawuleza ii-oveni zabo zokubuyisela kwakhona ngeoveni ezikumgangatho ophezulu emva kokutshintshela kwimveliso engenalothe.

Ixesha lokuposa: Aug-10-2020