Zeziphi iimfuno ezintsha inkqubo ekhula ngokukhula engenalo ilothe eyibeka kwi-oveni yokugalela kwakhona?

Sihlalutya kule miba ilandelayo:

l Ungawufumana njani umahluko omncinci wobushushu obusecaleni

Ekubeni ifestile yenkqubo ye-solder-free ye-solder incinci, ukulawulwa kwe-lateral yeqondo lokushisa kubaluleke kakhulu.Iqondo lobushushu kwi-reflow soldering lichaphazeleka ngokubanzi ngezinto ezine:

(1) Ukuhanjiswa komoya oshushu

Ii-oveni zangoku ezingenalo i-lead-freeflow oveni zonke zamkela i-100% yobushushu obugcweleyo bobushushu bomoya.Ekuphuhlisweni kwee-ovens zokufudumeza kwakhona, iindlela zokufudumeza kwe-infrared nazo zivele.Nangona kunjalo, ngenxa yokufudumala kwe-infrared, ukuxutywa kwe-infrared kunye nokubonakaliswa kwezixhobo zombala ezahlukeneyo kuyahluka kwaye umphumo wesithunzi ubangelwa ukuvinjelwa kwezixhobo zokuqala ezikufutshane.Zombini ezi meko ziya kubangela ukungafani kobushushu.I-solder-free solder inomngcipheko wokutsiba ngaphandle kwefestile yenkqubo, ngoko ke itekhnoloji yokufudumala kwe-infrared iye yapheliswa ngokuthe ngcembe kwindlela yokufudumala ye-oven reflow.Kwi-solder-free soldering, umphumo wokushisa ukushisa kufuneka ugxininiswe.Ngokukodwa kwisixhobo sokuqala esinamandla amakhulu okushisa, ukuba ukuhanjiswa kobushushu okwaneleyo akukwazi ukufumaneka, izinga lokufudumeza ngokucacileyo liya kuba semva kweso sixhobo esinamandla amancinci okushisa, okubangela ukuhluka kobushushu obusecaleni.Makhe sijonge iindlela ezimbini zokuhambisa umoya oshushu kuMfanekiso 2 kunye noMfanekiso 3.

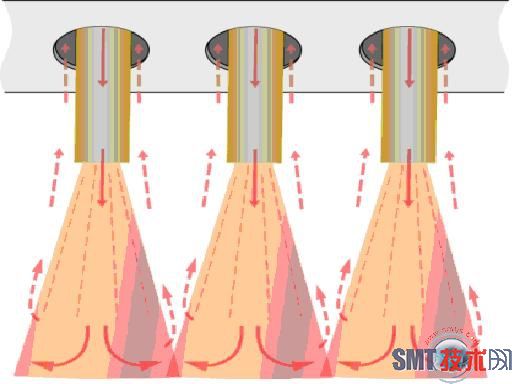

Umzobo 2 Indlela yokuhambisa umoya oshushu 1

Umzobo 2 Indlela yokuhambisa umoya oshushu 1

Umoya oshushu kwi-Figure 2 uphuma kwimingxuma yokufudumala kweplate, kwaye ukuhamba komoya oshushu akunayo isalathiso esicacileyo, esinokungcola, ngoko ke umphumo wokushisa ubushushu awulungile.

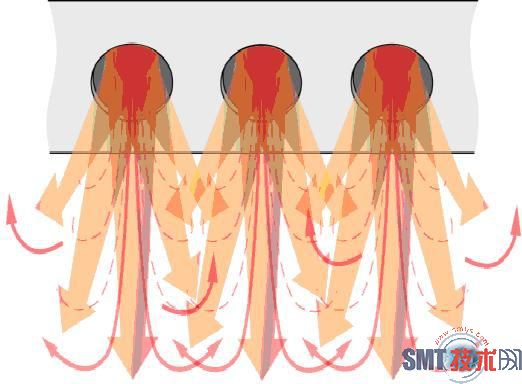

Uyilo lwe-Figure 3 luxhotyiswe nge-directional multi-point nozzles zomoya oshushu, ngoko ke ukuhamba komoya oshushu kugxininiswe kwaye kunendlela ecacileyo.Isiphumo sokufudumeza ubushushu somoya oshushu sinyuka malunga ne-15%, kwaye ukonyuka kwesiphumo sokuhambisa ubushushu kuya kudlala indima enkulu ekunciphiseni umahluko wobushushu obusecaleni kwezixhobo ezinkulu nezincinci zomthamo wobushushu.

Uyilo lwe-Figure 3 lunokunciphisa ukuphazamiseka komoya osecaleni kwi-welding yebhodi yesiphaluka kuba ukuhamba komoya oshushu kunendlela ecacileyo.Ukunciphisa umoya osecaleni akunakuthintela kuphela iinxalenye ezincinci ezifana ne-0201 kwibhodi yesekethe ekubeni ivuthelwe, kodwa kwakhona ukunciphisa ukuphazamiseka phakathi kweendawo ezahlukeneyo zobushushu.

(1) Ulawulo lwesantya setsheyini

Ukulawulwa kwesantya setsheyini kuya kuchaphazela ukuhluka kobushushu becala lebhodi yesekethe.Ngokubanzi, ukunciphisa isantya setsheyini kuya kunika ixesha lokufudumeza ngakumbi kwizixhobo ezinomthamo omkhulu wobushushu, ngaloo ndlela kuncitshiswe umahluko wobushushu osecaleni.Kodwa emva kwayo yonke loo nto, ukusetwa kwejika lobushushu besithando somlilo kuxhomekeke kwiimfuno ze-solder paste, ngoko ke ukunciphisa okungenamkhawulo kwesantya sekhonkco akunanyani kwimveliso yangempela.

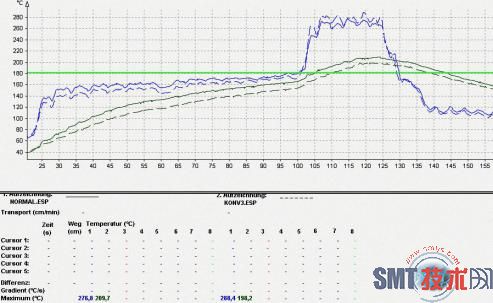

(2) Isantya somoya kunye nokulawula umthamo

Senze uvavanyo olunjalo, ukugcina ezinye iimeko kwi-oven reflow zingatshintshi kwaye zinciphisa kuphela isantya se-fan kwi-oven reflow nge-30%, kwaye iqondo lokushisa kwibhodi yesekethe liya kuhla malunga ne-10 degrees.Ingabonwa ukuba ulawulo lwesantya somoya kunye nomthamo womoya lubalulekile kulawulo lobushushu beziko.

Ixesha lokuposa: Aug-11-2020